Technology & Quality

Glulam Curves

Our products undergo strict quality control in laboratories (ISO, TÜV, PEFC®). Glulam arches are manufactured from high quality European coniferous timber cut into layers and laminated in a powerful hydraulic press to form their final shape.

In the last 25 years we have tested most of the world's leading glue, machinery and tool brands, adding our own patented solutions to create a technologically unique production process - our factory computers will turn the most elaborate shapes into products in just 40 minutes. If you are looking for a bespoke product - we are the best choice there is.

Machinery

Modern machinery and the use of high quality raw materials enables us to produce structural arches with a span of up to 26 m and radius from as little as 30 cm.They are characterized by high strength and best quality in accordance with EN 14080 - GL 24 C standard. During manufacture process we use premium grade timber, which is selected and dried to 18% humidity. It is then sliced into thin laths with thickness ranging from 2.8-45 mm by precise saws (allowing for 1.15 mm waste on 9 mm batten) and producing a glue-optimised surface 88 % yield. Glue spread is also CNC optimised. We shape curves with high frequency hydraulic presses achieving 12 kg/cm2. Planing and drilling is made by 5-axis CNC Shaper and digital centres producing 4000 units/shift.

Pressure treatment

Impregnation of our glulam curves is usually carried out using a specially designed vessel called autoclave. Inside the autoclave, preservatives like fungicides and insecticides are injected under pressure into the wood. Thanks to formation of a vacuum, impregnation salts penetrate the curves much deeper than in the traditional dipping method. During impregnation we use super ecological - latest generation preservatives called Tanalith E® and Osmose®. Just after this process, curves get a greenish color, which in time turns to honey one and finally to silvergrey, what gives invaluable natural but unique outlook of every arch treated.

How is it made?

Modern machinery, patented technological solutions and use of high quality raw material, enables us to produce structural arches with a span of up to 26 m. All our products are characterized by high strength and quality in accordance with EN 14080 - GL 24C standard.

Only premium grade raw material is selected to manufacture our glulam curves. Timber is sliced into thin laths by precise vertical saws. Glueing in class D4 is CNC optimised, we utilize only world leading certified suppliers. To form desired shape of curves, we use high frequency hydraulic presses. Planing and drilling is made by 5 axis CNC shaper and digital centres.

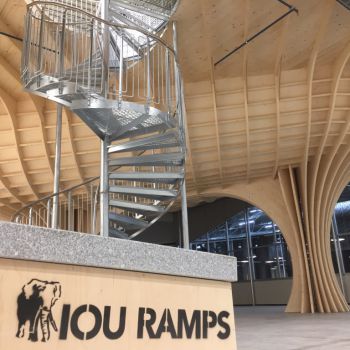

How do we and our customers use our bespoke timber curves

Interested ?

We are passionate about outstanding projects using laminated arches. We know that laminated, arched wooden curves can be used to make more versatile structures, consuming less natural resources, safer in a fire, with a better strength-to-weight ratio than concrete or steel constructions. That's why we spent years working on machine design and manufacturing process that today allows us to create any shape of laminated wood in less than one hour at a very reasonable cost. Talk to us about your most challenging projects - we will probably be able to implement them.